ISOLATING TRANSFORMER

Runway Edge High Intensity Bi-Directional Elevated Light AMA AUN -942

FAA : In compliance with FAA AC 150 / 5345 – 47 A.

ICAO : In compliance with ICAO recommendations.

I. S. : In compliance with Indian Standards: 12290-1987

The Series Isolating Transformers are utilized in constant current series circuits for Approach, Runway, Taxiway, PAPI and other lighting to:

- Isolate the low voltage lamps from high voltage series circuits which are connected to constant current regulators.

- Ensure the continuity of the series circuit in case one or more lamps are burnt out.

- Highly Reliable due to rigorous testing at each stage of manufacture. After production each transformer must pass dielectric test at 15,000 volts D.C.

- Neoprene Rubber Encapsulation at high temperature and pressure makes the transformer extremely durable. The transformer is acid and oil resistant and will also withstand U.V. Radiation, Ozone, Salt, Sodium and other chemical agents.

- Completely Watertight as the cables form an integral part of the transformer and are moulded in the transformer body.

- Shock and Impact Resistant due to elasticity of the rubber encapsulation.

- Added Safety due to complete separation of the primary and secondary windings.

- Low Power Loss due to C-core or Toroidal core made of grain oriented steel laminations resulting in high operating efficiency.

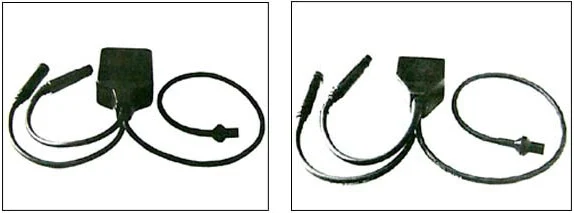

1 Magnetic C-Core

2 Primary and Secondary Windings of Super Enameled Copper Wire

3 Polyester Insulation

4 Epoxy Encapsulation

5 Neoprene Rubber Coating

6 Single-core 5 KV EPR / PCP Primary Cable

7 Twin-core 1.1 KV EPR / PCP Secondary Cable

8 Moulded Two-Pin Receptacle, FAA L-823

9 Moulded Single-Pin Plug, FAA L-823

10 Moulded Single-Pin Receptacle, FAA L-823

The Isolating Transformers are available in either C-core type or Toroidal core type. The primary and secondary windings are made of super enameled copper wire. Two EPR primary cables of 5KV grade with factory moulded plug and receptacle and one EPR secondary twin-core cable of 1.1 KV grade with a factory moulded two-pin receptacle are connected to the windings. The entire assembly is then epoxy encapsulated in a vacuum chamber. Finally, the transformer is moulded at high temperature and pressure with specially compounded moisture resistant neoprene rubber. On request, the Isolating Transformer can be supplied with a provision for earthing the secondary winding and core as recommended by ICAO.

The AMA Isolating Transformers with plug and socket arrangement are designed to be buried directly into the ground. However, for ease of access, it is recommended to install the transformer in concrete or masonry pits or specially designed transformer housing boxes.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|